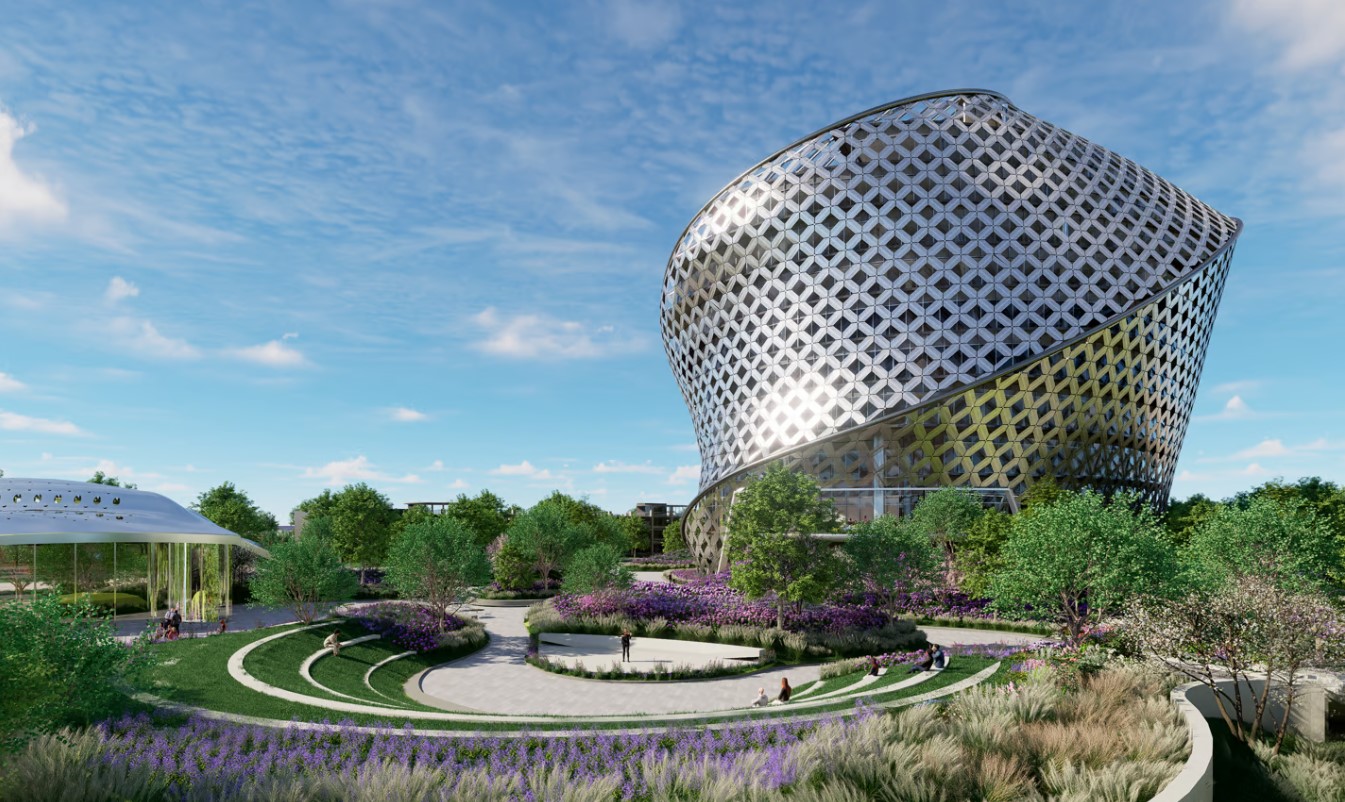

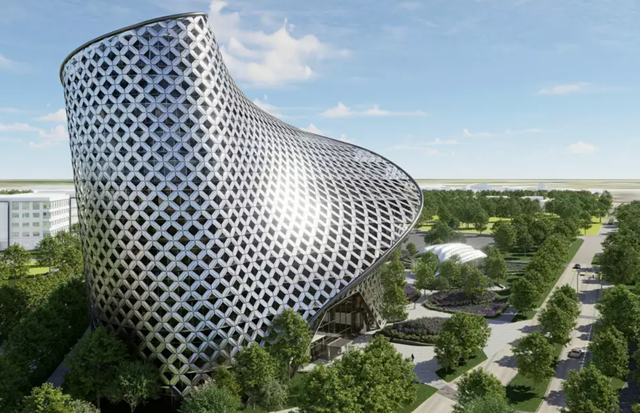

Goods can be safely flown to areas of the world where they are urgently needed.

10-04-2023

Downloadable Version

SAN ANTONIO, TX — Port-based Knight Aerospace has teamed with fellow aerospace firm Recoil — based in Madisonville, Tennessee — to develop new technologies that will allow the defense community, humanitarian organizations and other cargo aircraft operators to more efficiently deliver water and fuel supplies to locales where they are urgently needed, such as areas impacted by natural disasters, military conflict or which are otherwise remote and difficult to access.

The two products — High-capacity Air-transportable Replenishment Palletized System (H.A.R.P.S.) and Oasis — are 1,000-gallon units that allow for the safe and efficient cargo transport of fuel and water, respectively. They can be delivered by helicopter or fixed-wing aircraft.

The units are a departure from traditional methods for the transportation of large amounts of liquids by air. Traditionally, the military and others have relied on 'bladder' systems — essentially large bags that are placed and secured by tie-downs in a cargo hold before they are filled with liquid. Upon arrival to their destination, the fuel or water within is removed by hose systems, since the bladders are too large and unwieldy.

By contrast, the new units by Knight and Recoil can be quickly loaded and off-loaded from the aircraft full of liquid — reducing the amount of handling time and personnel required. Unlike bladder systems, they can be secured to the hold of current cargo aircraft handling systems without tie-downs required. Their smaller size also means that they can be easily moved by forklifts and loaded into a wide array of everyday ground transportation, eliminating the need to have tanker trucks at the ready. And with a 20-year lifespan, each unit will be able to fulfill a significant number of missions.

Photo credit: Knight Aerospace.

The H.A.R.P.S. and Oasis units underscore the expertise of the two companies.

For nearly 30 years, Knight has been at the forefront of developing products that can be quickly rolled onto a vast array of cargo aircraft for multiple uses, including palletized seats, galleys and lavatories that can convert aircraft for passenger use to modular aero-medical units that allow those same aircraft to serve as 'flying emergency rooms' — able to transport and treat injured or seriously ill patients while in flight. Most recently, the company secured a U.S. Air Force Grant of nearly $4 million to advance the development of systems for transportation of cargo through space.

Recoil specializes in the development of high-grade industrial carbon fiber tanks that are relied upon by military and commercial operations, including its renowned Tsunami products, which are used in combating wildfires.

"We are very excited about our newest partnership and by our ability to have so rapidly developed a new system that will be making a world of difference," said Knight President and CEO Bianca Rhodes. "We are confident that the aircraft operators, their support crews and, most importantly, those on the receiving end of urgently needed water and fuel will see an immediate benefit thanks to an innovative technology that is easy to use, scalable and safe."

About Knight Aerospace

Knight Aerospace specializes in designing and manufacturing customizable palletized and modular systems for cargo aircraft, trusted by major military, civilian and aircraft OEM organizations worldwide. The company's innovative solutions are engineered for safety, durability and precision, ensuring rapid mission readiness. Learn more at www.knightaerospace.com.

About Recoil

Recoil designs and manufactures lightweight carbon fiber Tsunami wildfire suppression tanks and fluid utility cargo tanks for military and commercial operations globally. Learn more at www.recoil-usa.com.